C2A Series

Pre-attached cables for faster, easier gage installations Linear, Shear and Tee- and rectangular rosette patterns with polyimide encapsulation Low cost alternative for test temperature to +180ºF (+80ºC)

|

L2A Series

Pre-attached ribbon leads for faster, easier gage installations Linear, Shear and Tee- and rectangular rosette patterns with polyimide encapsulation Low cost alternative for test temperature to +250ºF (+120ºC)

|

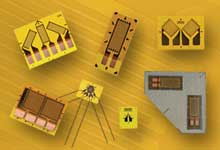

Stress Analysis Strain Gages

Micro-Measurements maintains the most extensive variety of catalog strain gages available today. Whether for stress analysis, transducer manufacturing, or special-purpose applications, we have not only a wide selection, but also a large and varied inventory that is readily available for immediate delivery.

|

| |

|

|

Linear Patterns Strain Gages

Gage patterns designed for measuring strain in a single direction Single-grid and parallel dual-grid patterns Gage lengths from 0.008” (0.20 mm) to 4.000” (101.6 mm)

|

Tee Rosettes Strain Gages

•Gage patterns designed for measuring orthogonal strains All patterns have two grids oriented at 0° and 90° angles Both stacked and planar constructions available Gage lengths from 0.050” (1.27 mm) to 0.250” (6.35 mm)

|

Rectangular Rosettes Strain Gages

Gage patterns designed for determining principle stresses and strains All patterns have three grids oriented at 0°, 45° and 90° angles Both stacked and planar constructions available Gage lengths from 0.031” (0.79 mm) to 0.250” (6.35 mm)

|

| |

|

|

Delta Rosettes Strain Gages

Gage patterns designed for determining principle stresses and strains All patterns have three grids oriented at 0°, 60° and 120° angles Both stacked and planar constructions available Gage lengths from 0.30” (0.76 mm) to 0.125” (3.18 mm)

|

Shear/Torque Rosettes Strain Gages

Gage patterns designed for measuring shear strain and torque Individual and multiple grid patterns Gage lengths from 0.062” (1.57 mm) to 0.250” (6.35 mm)

|

SR-4® Strain Gages

SR-4® (Constantan Foil, Polyimide Carrier) Strain Gages

|

| |

|

|

Residual Stress Strain Gages

The most widely used practical technique for determining residual stresses is the hole-drilling strain gage method described in ASTM Standard E837. With this method, a specially configured strain gage rosette is bonded to the surface of the test object; and a small, shallow hole is introduced into the structure, through the center of the gage, with a precision drilling apparatus. Strains in the immediate vicinity of the hole are measured, and the relaxed residual stresses are computed from these measurements.

|

Magnetic Field Strain Gages

Intense, time-varying electromagnetic fields with steep gradients in field strength can cause troublesome noise in strain gage circuits. In severe magnetic environments, with low signal levels, the noise amplitude may be several times larger than the strain signal from the gage.

Micro-Measurements H-Series noninductive strain gages have been specially designed to minimize noise pickup in the gage grid due to electromagnetic fields.

|

Weldable Strain Gages

Micro-Measurements Standard Weldable Strain Gages and Temperature Sensors are specially designed for spot welding to structures and components. They are ideal for applications where test or environmental conditions preclude clamping and curing an adhesively bonded gage installation. These gages are equally advantageous

when strain measurements must be made at an elevated temperature, but the nature of the test object does not permit the use of an elevated temperature-curing adhesive.

|

| |

|

|

High-Temperature Strain Gages

-

Measurement range to 2100°F (1150°C)

-

Free-filament Kanthal alloy grids for bonding with ceramic adhesives

-

Linear and Tee-rosette patterns

-

Video - Strain Gages in High Temperature Environments

-

|

Shear Modulus Testing Strain Gages

Shear Modulus Sensors are specifically designed to accommodate the unique specimen geometries and strain-field distributions encountered when testing

composite materials for shear properties. Two popular specimens for in-plane shear modulus testing of composites are the Iosipescu and compact designs. The test section for both types is described as the

area between two opposing notches.

|

Weldable Strain Gages

Micro-Measurements Standard Weldable Strain Gages and Temperature Sensors are specially designed for spot welding to structures and components. They are ideal for applications where test or environmental conditions preclude clamping and curing an adhesively bonded gage installation. These gages are equally advantageous

when strain measurements must be made at an elevated temperature, but the nature of the test object does not permit the use of an elevated temperature-curing adhesive.

|

| |

|

|